I’ll try it out tomorrow, then bend the clips out if I’m not getting enough pressure on my tall storefronts. I just figured the end clips would pull water better from edges given the angle change. I detail in almost every case as there’s always some water left, so we’ll see…

You really shouldn’t need to detail when using a liquidator channel. Especially if there’s seals.

If you have zip ties, or clips,to hold your rubber that wouldn’t be a problem.

If you still need to detail on the glass I would keep training on the technique.

With the liquidator you can’t go to fast. Better to slow down a little and be precise.

I do some old and big single pane A-frame type storefronts with bumpy seals. I generally use a sorbo for those, but I’ll see how it works on bumpy seals.

Aha, bumpy seals. Then maybe you have to detail…

Sorbo is king  ️️

️️

It’s dribbled silicone… My 24" sorbo has been fastest so far with the overhanging rubber, but want to learn new ways to clean uppers and stay on point with new tools. Makes it fun!

The Excelerator was great today! I used it for pole work and in hand. I just kinda kept it in my hand; wasn’t sure where to put it. It was good as a liquidator too. The zipties fell out, but I think the extra sorbo clips may be perfect.

Tricky tool. You have to apply pressure, but be light on the seals, or it catches. Very little detailing.

The toughest part was finding a pole that worked for it. I have wood cones on all my poles and it kept spinning on the cone. Bought an unger that I just jam the handle onto, which is working for now.

My 14" fits nicely in my unger ninja boab.

I use the unger optilock. It fits perfectly and even locks. I was surprised the hole lined up with the peg so nicely.

I’m not really surprised by that unger seems to be the dominate brand in the UK.

I’m going to drill holes so I can use it with both ettore and unger poles.

My ettore pole tip was too small for the excelerator and allowed it to spin free of the locking button. Unger tip locks up perfect though.

Thats what i tought

There you go.

So I think I’ve solved the issue that myself and others were having, with the liquidator channels (especially the 2.0) completely missing solution about half an inch from each end, and even missing solution or leaving lines of water in the middle of the channel. At first it seemed to be from the rubber being able to fold up in the hollow spot created by the forward bent tips. After some more thought and comparison to my 14" modified wagtail, I finally realized the issue and apparently have corrected it.

My modified wagtail doesn’t have the rubber clipped in the ends, yet the tips (inflexible metal) are bent forward (although not to the degree of Liquidators) yet performs flawlessly on being detail free.

I was using my my 10" Liquidator 2.0 channel yesterday when I realized this; so I completely removed the section of plastic in the clips that pinch the rubber in place, and shaved some plastic off the other side (the bottom ‘tip’ of the clips) to allow the rubber to move freely like it would on my wagtail. I then cut the outer teeth off the Excelerator handle (this may have been unnecessary, but I have 2 handles) so the rubber is only secured with the middle tooth, also similar to my wagtail (rubber secured by a crimp in the channel).

The above actions completely solved any issues I was having with the rubber missing solution, leaving lines/streaks, not being “detail free”, etc… It now performs as it should, and blades the solution off the glass completely as my square cut standard channels do (Ettore brass/superchannel, Unger).

I would recommend anyone having the same issues (leaving water just inside the ends, even on straight pulls) remove the small section of elevated plastic in the clips that pinch the rubber in place. I also believe this would fix rubber “shrinking” issues (I also have this) because the rubber wouldn’t be stretched, or need to be stretched, at any time while in the channel.

Any chance of posting some pics? Sounds interesting.

Agree. Would be really interesting to see some pics.

Normal Clips:

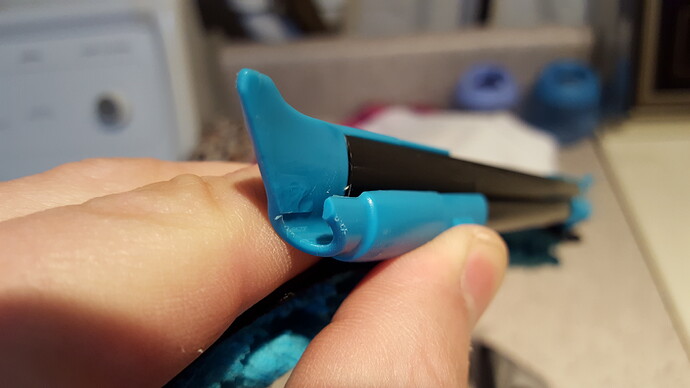

Modified:

It’s not a “clean” modification because all I had was my 1 1/2" scraper to do it. You can see that elevated piece of plastic is shaved off; if you can, make it flush. I also shaved a tiny bit off the small tip of the clip across from it, just to open up the area a bit to make sure the rubber is able to move freely.

Thinking about clips and why this has such a significant impact: Ettore brass clips surround the lower part of the rubber, being equal width’s on either side, allowing the rubber to sit centered in the channel along the entire width/length of the channel. In the Liquidator 2.0, the plastic pinch is only elevated on one side, forcing the bottom of the rubber forward at the very ends, creating a ‘bulge’ at the top. So the primary goal of this mod is to allow the rubber to rest centered in the bottom.

Let me know what yall think, try it for yourselves, just do a better job than I did! ![]() Dremel with a flexible sandpaper disc is my go-to for mods like this.

Dremel with a flexible sandpaper disc is my go-to for mods like this.

Thanks for sharing the pics and the tip, Brian!

Ok so I did this mod today and it helped a little, but still didn’t solve the issue completely. Has anybody got some 1.0 clips for sale?

I haven’t read thru this ponderous thread to find out what the issue was exactly. However, I don’t think I need to.

But Sam, my estimation is that 90% of all issues relates to not having enough solution on the window.

This then leads to adding more pressure. (HUGE misconception. Always add more solution to keep your feather touch.)

One should be able to glide along holding it just with fingertips.

If rubber is sliding excessively, another technique is to make sure your leading edge tip is no more than an inch above solution at all times.

Finally, Hanglide, Hanglide, Hanglide. At least at the beginning.

We are going to break down LQ techniques just like we did with Team Technique because they are altogether different from trad squeegees.

All the Techniques we’ve discussed for trad squee is based on dry, dry, dry. Dry that rubber.

LQ is just the opposite. Wet, wet, wet.

Try it out and see if it solves for Mate.

Yup I’ve already been through that. I mix my solution heavy on the soap anyway, and I always like a wet mop.

Up until now, I’ve been using zip ties in the ends to secure the rubber. With zip ties in, I can use a feather touch and my edge is cut in perfectly. I don’t leave any drag lines or rainbows. This tells me my technique is on point.

My problem is I really don’t want to use zip ties, or any other kind of clip for that matter, since that’s not how this squeegee was designed to be used. I want to pop in a rubber and go to work, just like with any other squeegee, just like I used to with the old liquidator.

But when I take my improvised clips out, the ends start streaking. Not from the extreme edge as has been noted to happen when the amount of slip/solution is insufficient. From about 1/2 inch inside the edge. If I really bear down hard, it goes away. That seems like a recipe for carpal tunnel to me. With the end clips shaved out and the two outer teeth ground down like @bcox posted, the required pressure is lessened, but still much more than it should be.