I do a lot of rural windows and want to use a WFP. Will the hardness of well water use up the resin in the de-ionizer? What other forms of filtration could I use to prolong the life of the resin?

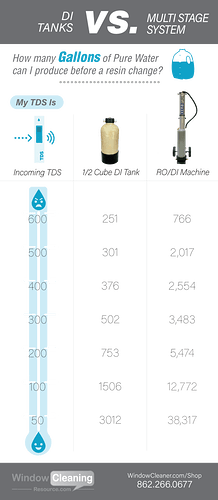

yes it will eat it up quick,you can also use carbon sedimnet and ro membrane. @Chris has a cool chart that tells di resin consumption at different tds levels but i can’t remember where it is

Use a tank… stop filtering on site. Carry pure water with you with 12v 100psi 2 gpm and you are good to go bro.

How big of a tank would i need? It needs to fit into my truck.

Depends… we started with a 65gal. We could do up to $1k with that. But we carry abou 200gal now. I found a cargo van with a tank to be the way to go. Employees pull up and are working within literally minutes at a house

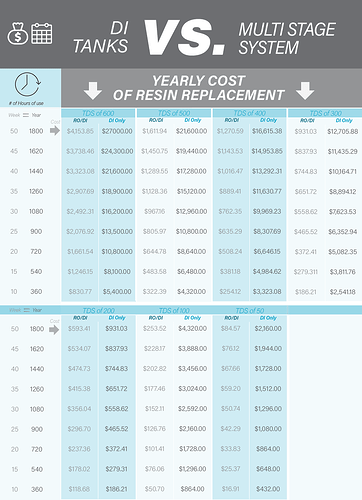

If you have Hard Water the most cost effective thing you can do is use an RO. This graph below assumes 25 hours of use per week for 36 weeks a year.

I used to think & a lot of people say if you have under 100tds DI is more cost effective than RO/DI. But I was wrong it is really more around the 50 TDS range. As you can see by the chart unless you rarely use your system or have TDS under 50, there is almost no circumstance where DI only will be more cost effective in the long run.

This winter I put a lot of thought and calculation into this. 50 is the magic #!

I honestly don’t think it’s worth worrying about if you have an RO/DI system. According to @Chris at max it’s gonna cost you a couple bucks an hour to run.

The safety and speed of a WFP is pretty much always going to outweigh the cost of resin.

If you have a low PPM water source at the house or shop then the tank based system is the way to go. You can get this one https://shopwindowcleaningresource.com/remote-chemical-delivery-system-for-fill-n-go.html or you can build your own with this kit https://shopwindowcleaningresource.com/rhg-delivery-kit.html

Let me know if you need any help setting it up