So I tried hooking up my new controller last night, thought I had everything all set, put the 10a fuse in place, and it popped the instant I put it into the holder.

@Iansheppard, I’m not sure what to check for. The pump might have been under load when I attached the controller, so my guess is I have a small leak somewhere and it tried pushing the pump the instant it was plugged in?

I didn’t wire the orange charging wire to anything, since I only have one battery on my rig. I double checked polarity on the power supply and pump, and it all looked good.

Make sure your pump power and control power aren’t reversed. I had the same problem blowing a fuse after I had disconnected mine and I had inadvertently crossed those two wires (because European colors don’t exactly match our wiring code).

Thanks Wagonhound My initial thought was that the polarity may have been reversed. In the event this happens the +12V circuit in the controller is shorted to ground and damages the circuit. Then each time a fuse is fitted the the damage to the PCB shorts to ground and pops the fuse.

Good point re cable colors. Please see the video guide link: Spring (Europe) LTD - V11 Charger Pump Controller Video Manual - YouTube

Cheers

Blue to black, brown to red, correct? I’ve dealt with the european color standard before when installing an LED power driver. I don’t think I got the polarity reversed. But haven’t had a chance to triple check it yet. I might have some time today if it stops raining here.

This is the pump wiring to the controller.

1 Like

@Infinity Alex, you figure it out?

Not yet. Been kinda lazy, tbh.

Hi Alex, Yes the V11 to pump connections are

Controller Brown (+12v) to Pump Red

Controller Blue ( Negative) to pump black

Then the connections controller to battery should be

Controller Red ( +12V) to battery positive terminal

Controller Black ( Negative) to battery negative terminal

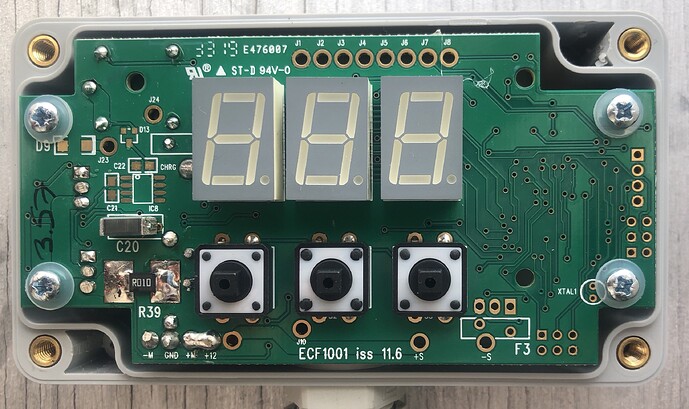

Miss connection of the battery to controller shorts the +12V circuit to ground and blows the diode. Once this has happened each time a fuse is fitted the +12V circuit grounds and will blow the fuse instantly. A picture of the PCB would help me if that possible

Nothing looks scorched to me.

The pump I’m running it with:

Hi Alex. Thank you for the picture that helps a lot. As a proviso an image can be affected by light and shadow so can be different to holding the controller in my hand. Based on the picture looking closely at the PCB it appears there are water droplets just below the J23 and by C22. The droplets are sitting on the top pin of a FET. This component is part of the +12V circuit and if it has had water on there it would short the circuit and cause the fuse to blow.

There is also a possible sign of water on the two pins between the button push and the R010 component the solder appears dulled. But again that could just be the light effect of the camera.

If you have a test meter we can test for the short. between the numbers 3.57 and C22 there is a line on three soldered pins this is the top FET. Putting a test meter on the top and bottom pins should see a circuit if there is no amps there the circuit has shorted.

It is also worth testing the bottom FET in the same way ( the three pins between the posidrive screw and R010)

Sorry not to be able to give more positive news

I’ll have to open it up again to be 100% sure, but I believe that any droplet-looking things were actually an adhesive/silicone of some sort. I think actual water would’ve jumped out at me, so to speak.

I’m really hoping that I just pulled enough startup amps with the pump already being in an “on” state when I plugged in the fuse, that I just popped it that way. I know motors can pull more amps on startup than what their rated operating amps indicate.

What should happen with the controller connected to power, but not connected to the pump? If it turns on, then I should be good, and it’s probably an issue of the pump pulling too many amps, right?

Hi Alex. Yes it is possible that the droplets are silicon, while pictures can help, they can be a little deceptive due to the way light falls.

Your assessment of high current draw by the pump as the fuse was placed is a valid one. The pump is a max 8a draw, with the fuse being 7.5a. It is possible that a large spike of current draw from the pump could blow the fuse.

Yes connecting the controller to the battery with the pump disconnected should see the controller power up. As it powers up the controller should display a Flow rate and PS ( pressure switch, it will show PS at this point due to the pump being disconnected. At this point I would suggest turning the flow rate to 0 before connecting the pump. If the Fuse blows when the pump is connected we know where to look next. Hopefully it will work as we expect. and you can then go into the menu and set up flow rates and calibration.

Please see the following link

In the event the controller does not power up Spring do offer a inspection and repair service, But it would need to come back to the UK via a standard postal service. Fingers crossed this is not needed. and thank you for the information and images

Hooked it back up without the pump, and it popped the fuse instantly. Slight odor of burnt pcb. Still no visual damage that I could detect. Droplets were little globs of silicone, as I suspected. Polarity of my power supply is correct. Pump runs just fine plugged in directly. It just cycles like mad from all the hose I’m running.

I don’t have a multimeter with me at the moment. But not sure what good further diagnosing would be to me. I wouldn’t be comfortable attempting to swap out any components on the circuit board myself. My soldering skills were never that great, even in electronics shop. I’m sure they haven’t gotten any better in the last 15 years

Thanks for the update. The acrid smell and that the fuse opened instantly on connecting the battery are conclusive. The protection diode we place on the PCB to protect the processor from reverse polarity has been shorted

The diode is placed on the power circuit so that in the event of an accidental miss connection to the battery and polarity is reversed and the +12v is grounded that the diode goes short circuit.

The controller can be repaired but it will need to be returned to Spring in the UK to do this as we will also check the power circuit. Repair is £37.90. The controller can be returned to us using a standard postal service.

The New V16 pump controller features a different reverse polarity protection technology. The New V16 detects the reverse polarity and will not power up until the connections are corrected

Bummer.

When does the V16 hit the market? I might just get another cheapy PWM from Amazon to hold me over until the new version is out.

The V16 is in production. Suggest you contact the guys at WCR and they can put the wheels in motion on this.

Cheers

^^^^^^

@Chris, @Alex, @Jersey, @TheWindowCleanse, @John, let’s make it happen.

Btw, Jersey warned me that these controllers can be finicky. I didn’t realize that meant they might randomly fry themselves right out of the box.

I’m not a novice to electrical components. I know that I didn’t crosswire this unit at any point. There was no, “oh crap” moment where I finally realized what I did wrong. I am more than happy to own up to mistakes when I make them, and I’ve unfortunately made more costly blunders in the past, than frying a $150 controller.

I’m usually not one to make a stink about stuff, but I’m just not satisfied with the offer of shipping this unit to the UK for $50 + postage for repair.

While I appreciate your frustration it should be noted that I am sat in the UK late into an evening offering advise and support.

To put into context your comment regard "Finicky " Your are experienced professional and if having cleaned a clients property they call a few days later to complain about marks on the windows and it must have been when the windows were cleaned so want you to go fix it. On arrival at the site the windows indeed have marks on them, But when the windows were cleaned the window frames were Blue and now there are White and the marks are Paint. Despite the customer adamantly saying this is not the case and it must be the fault of the cleaner. The conclusion here is obvious and Clearly not due to the window clean.

Spring are a professional electronics company and have been designing and producing pump controllers for some years together with a range of electronics going into other markets. The controllers are designed and built in house from the base board up. Every controller we build is fully tested before it leaves the workshop and is shipped. As part of our testing we do carry out destruction testing from time to time as such we know exactly how the controller can be damaged and what causes the damage.

The V11 controller and the V9 variant before it have had a protection diode fitted to the power supply for 11 years. The diode was fitted due to controllers being damaged beyond repair on miss connection to the battery. Fitting the diode meant that when a mistake occurred the controller was repairable at a lower cost than replacement.

The Diode is deliberately placed in the circuit so it will blow only in one set of circumstances. The controller its self has no means of producing power it has no internal power supply. For it to be damaged by a short circuit the power to create the short can only be external to the controller. While it may be an uncomfortable truth the controller has been miss connected to fail in the way described.

My conclusion is not based on some random guess it is based on the information provided and experience of the product.

If you would like the controller repaired we can offer that service.

1 Like

I appreciate you taking the time to try and help me. I do not think many of your customers expect answers the same day, especially if they are aware of the time difference. But it is appreciated.

I think I might’ve accidentally gotten a unit that was returned to WCR in nonworking condition. I just can’t figure out how I could’ve switched the polarity on something after triple checking, and successfully using that same polarity with just the pump and no controller.

At any rate, you’ve done your due diligence in trying to help.

If you could point me to the correct diode to replace, I will attempt to swap it myself, at my own risk. I have a hard enough time returning packages to Amazon, when they provide me a return label and everything. So I’ll take my chances with a DIY repair.

If I fail, I’ll try and get my hands on a V16, and will probably just use a cheap PWM in the meantime.

I think you guys do make some quality hardware, and put a lot of care into making a product that will be reliable. I think most people (window cleaners  ) are probably not electronically literate enough to install or operate them properly, resulting in the high rate of reported “finickyness”.

) are probably not electronically literate enough to install or operate them properly, resulting in the high rate of reported “finickyness”.