I hear you … Lows sucked when I took a knee … I don’t much like poling them but glad it works for you. … let me know when you have a video out I’ll have another here soon

Luuuuuuk this is your fellow window cleaner !!

Sorry had too ![]()

Ok so once you cut it down for that particular center. ( now remember I said its got to be a good amount of glass like that center your cleaning not one store but whole center ). Once it’s cut them marked after a while you will know ok this is the "Apple Bees center channel you wil come to know it .

Like gomer pile new is rifle in full metal jacket

Keep in mind you can still bend down if you’d like , but remember me when you hit 50. You’ll be like that freaking Majestic guy he was right one channel 10 bucks fucki it. I’m doing it !!!

It’s all coming back to me now I remember that one center I use to do at the end of the day. I use to pull in there an be like fuuuuuuuuck. Once a cut it down I was like ok let’s get er done

I have one store with 6 low Windows. That’s it. So needles to say i nbend … Well I send my helper over to do them  Ha !!!

Ha !!!

When I’m 50 I won’t be cleaning them at anymore …I’ll lol be like hey kid majestic was right huh

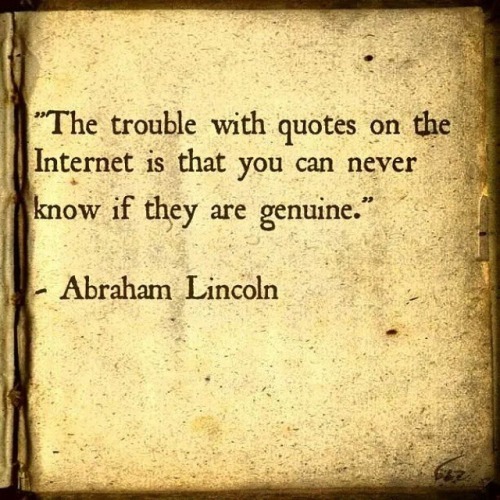

This debate over cutting channels reminded me of a quote I really like, that was attributed to Abe Lincoln:

“Give me 6 hours to cut down a tree, and I’ll spend the first 4 sharpening the axe”

The fact is, a guy could probably cut down this hypothetical tree with a dull axe in 6 hours. Heck, he could probably be done in 5. But he’s going to exert a lot more effort to do so. He’ll be hacking away for those long hours, while Abe is relaxed at his sharpening wheel, sharpening away. When Abe finally starts on the tree, the other guy is just about spent physically. Abe has the tree cut down with ease and only breaks a moderate sweat, while the other guy is completely exhausted by the time he’s able to whimper a pathetic, “Timber!”

Abe moves on to another project, while the other guy goes home and gets treated for heat exhaustion.

So even though I might take a little longer to select and use my custom cut squeegees, I still do it, because it saves me from unnecessary exertion and the potential for repetitive strain injuries. I believe in working smart and hard. But not harder than is really necessary.

Yeah, I have one channel cut for a series of fast food restaurants I do. I can bust out the lower windows with a pole pretty quick.I probably pole 90% of the lower windows. And I don’t have to worry about that little rock hitting me just right in the knee cap and totally jacking up my walk up for a week.

Ah, one of my favorites from Abe

Well guess get your sharpening stone . Lol yes if I did a hundred of these a day I would cut a channel. I cut channels for big jobs with tons of French panes . But for a once per month 30 panes…no. but hey just me . Cut away !

Yeah, to be totally honest, I probably wouldn’t cut a channel for just that job. Not because I don’t think it’d be worth it in the long run, but because I’m lazy and there’s no substantial short-term payoff. And I’m lazy…

And let’s just say I did start cutting channels for these type of jobs. I’d use a wide body channels. Now I have 100 store front accounts in the example. So let’s just say I’ll need 75 channels maybe I luck out and some are usable for other jobs. Low balling it I’ll need about $1,875 for channels . Let’s just say the jobs on average are $40.00 …comes up to $4,000…taken out our low balled channel cutting we got about $2125. If you plug in labor , and gas plus time for making all of them … and this is based on a one man operation. … What if you have more guys ? Do you buy another $1875.00 of channels or do you try to split the channels up every day based upon the work they are doing . Seems like a bit of a headache if you’re not a one man operation.

IMy boss never cut down channels for me . If I wanted to make it easier for myself them it was on me.

it doesn’t have to be a wide body a cheap stainless Ettore is fine

what’s wrong with 2 pulls instead of one I would still do it that way them bend down like your doing in the video

2 pulls now you don’t have to cut anything down

You can thank me later for the money I just saved you

-

No, I’d use stainless pulex channels - super cheap. We’re talking about a specific use channel.

-

You only really need maybe 1 special channel. Cut it for the size of the most common lower window in your route. If you have large 30" lower windows, use an 18" uncut channel for that.

-

If a few cut channels shaves off 5-10 minutes on a large storefront that you clean every 2 or 4 weeks, how much does that work out over the year?

Assuming $60/hr on route - 5 minutes gets you $65 per year on a 4 week stop. It gets you $130 on a 2 week stop. Double that for a 10 minute savings.

So for $65 bucks, I’d spend money on a $7 channel.

4 You don’t have to worry about that little rock messing up your knee. You hit that sucker just right and you’ll be walking like a pimp for a week.

5 It also saves wear and tear on jeans. So instead of $65 savings, add in a $30 pair of wranglers and you’re at $95 per year…

Time to get more comfortable jeans Jared! ![]()

Let’s follow your line of thought for a moment, and say you wanted a complete set of channels in 1/4" increments, between 4" and 20" long. That means you’ll need a total of 64 channels.

What I would do is buy 32 of the 24" Steccone featherlight channels. Each channel will yield 2 sizes when you cut it. And you’ll also end up with two 12" channels, so you could cut one of them down to make a few additional tiny channels for cutups, if you wanted.

Total cost of 32 of the featherlights right now is $400. Add a wcra discount of 5% (or 10% if you’re a year 2+ member), and that brings your cost down to $320-$360.

That, in my mind, would be a reasonable cost to outfit a vehicle with a complete set of custom-cut squeegees, if you encounter many cutup/true divide windows in your market. Not every employee would need their own set, just every crew. Guys doing outsides should probably be using wfp if there are a ton of cutup panes.

But… It doesn’t sound like you’re dealing with an overabundance of french panes. Just some storefronts with uniformly sized glass. If I were in your shoes (and I felt inclined to do this…), I would begin by carrying a small tape measure with me, and measuring the smaller panes that I come across. This should take an additional minute at each stop, but you’ll only need to do it once. Keep notes on the sizes and the quantity of the panes. Once you’ve gone through your whole route, take a look for the most common sizes, and start cutting some squeegees.

I think you’ll find a lot of common sizes. in the end, cutting just 10 or 15 custom squeegees might save a good bit of work in the long run.

But, as I’ve indicated before, I’m a bit of a hypocrite in this regard. There have to be a ton of identical panes (usually on a resi job) before I’m motivated to pull out the cutoff saw and cut some squeegees. If I see a bunch of identical panes on a storefront/commercial job, I’ll take a minute and see if I’ve already got a blade that fits, but if not, I’ll just get to work with what I’ve got.

(My apologies for the novel-length post)

Just something to think about, I didn’t read everything posted above.

I also try to avoid bending over to do the bottoms. I just use my 14" wagtail.

I would mop all those bottom windows, Then wagtail, start on the bottom sill pull up on the left side and rotate the pole pulling across the top ride up on the rubber seal to avoid any drips. Then place the wagtail back on the left and pull parallel to the ground to finish the bottom. Sill squeegge to clean the bottom frame. You will have to put towel on the pole to touch up the bottom left corner. I can do everything with a pole and my time is almost the same as bending/moving up and down.

Just FYI

Joe

I think I have a video somewhere if that was too hard to understand. If you would like to see it, let me know.

Joe

What’s up Joe ,

If you have a video I would like to see it for sure . Sounds like a good way to do them.

Might be a good use for that wag thing

I’m not really sure how to do this, so hopefully this works.

This is a couple of years ago, when I first started a friend f mine used to sub me a day a week of route work. This is one of his accounts. The video is long, I don’t know how to edit it down, but the bottoms start around 6:00. Hope this helps or maybe you can throw me a few tips. @Majestic66

Thanks

Joe

I have knee pads that I put on for any job that takes more than 1 minute of bending down. Then when I have to take a knee it saves my ass big time and I never worry about what I am kneeling on.